Screen Printing

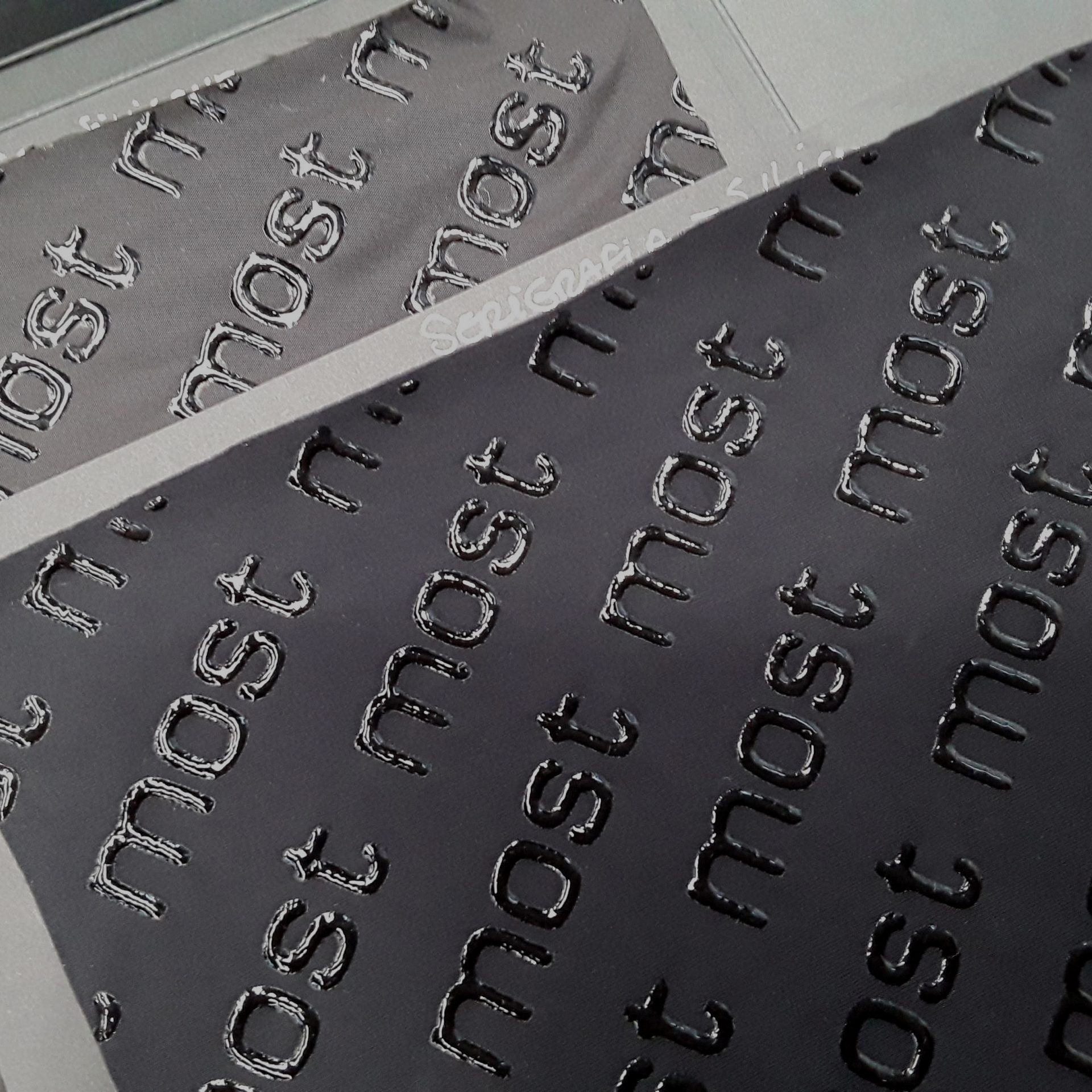

Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed.

One colour is printed at a time, so several screens can be used to produce a multi-coloured image or design.

FAQ about Screen Printing

What are the suitable materials?

Almost every kind: real leather, textiles, plastics, PU films, polyester fibers, etc..

What is this technique suitable for?

Screen printing is a technique that allows you to add color to a surface. The inks used can be created ad hoc, covering infinite ranges, or have tactile characteristics (such as flocking, glossy or matt, thicker, expanding) or metallic finishes (foil, glitter-shimmer). The inks can have chemical compositions : from plastisol, high density, water based, others.

It is necessary a mold?

The equipment needed for this technique consists in making a frame for each color used. A graphic file will therefore be necessary which, analyzed and processed, will allow us to “engrave” the material of the frame.