The widest range of processes for the Fashion & Luxury sector

All the processes are managed internally: this allows us to mix them to obtain always brand new results: “worlds” of reliefs, colors, finishes, craftsmanship superimposed on the most current and technological processes, to arrive at exclusive patents.

The Emboss world

The aim is to enrich a surface with an

emboss effect: that’s how you can add the brand personality on the material.

Create multiple levels, empty or full, with soft or rigid foams, with very small details or reliefs of large areas. Working with a single material or mixing many … all roads are open, because only in this way can meet every single need.

From our “core” High Frequency to the new and versatile HD-push up, changing the filling, one soft foam or a strongly defining silicon. Moving through patented techniques and exclusives such as SHF, Texflex, Dynamics and Ecodomes or chosing the very last one relief solution made of a mix of screen print and resins…

The Color world

Color is a power which directly influences the soul.

(Wassily Kandinsky)

If you agree or not with Wassily, it’s indisputable the importance of the color in the personalization matters.

We are strongly focused in giving you all the available option: UV digital printing and, for a more sustainable solution, the eco-solvent inks. Sublimation printing and the innovative LaserTransfer. Screen printing, screen printing transfer, Tampography and the brand new technique Tamp-foil.

A fully equipped airbrushing department allows us to propose handmade workmanships and leathers finishing…

The thermoapplication world

Personalization &

decoration for bags, SLG, shoes and accessories

Direct bonding on surfaces or thermo-applied overlapping: from low-thickness polyurethanes to leathers, from natural fabrics, such as wool and cotton, to the latest generation fabrics.

Whether it’s all-over coatings or logos and decorative textures, the thermo-application technique is always versatile and constantly evolving, thanks to the continuous search for new adhesives and also to the use of a special plasma machine that allows you to temporarily alter the porosity. of the various materials acting as adhesion promoter also of leather on leather.

The “Haute craft” world

The touch of an handmade

workmanship: this is adding value to each product

Mono and multi-material Intarsia, threading, weaving, stitching and embroidery, tapings and edging with a wide range of materials. Handmade dab color, airbrush shades, aging effects or brush strokes.

The strongest point is the possibility of mixing all the techniques because the whole departments is under the same roof.

RESEARCH & DEVELOPMENT

MOST-LAB

The company has always invested heavily in researching the most innovative technologies in order to expand its range of products and processes and be extremely proactive.

The fixed gaze on trends, the analysis of the complex global fashion scene, with its specificities linked to the geographic reference market, is the “compass” that guides us in ever new directions.

Colors, materials, techniques and technologies, sometimes far from the world of fashion, so thirsty for novelty, and today increasingly guided by topics such as eco-sustainability, respect for the environment and certainly a far-sighted look, never fixed on actual and always stretched on the future.

Most is focused on research to be able to give the right answers to the questions of a group of customers who are already sensitive to these issues.

This is the commitment to research and this is where new ideas come from!

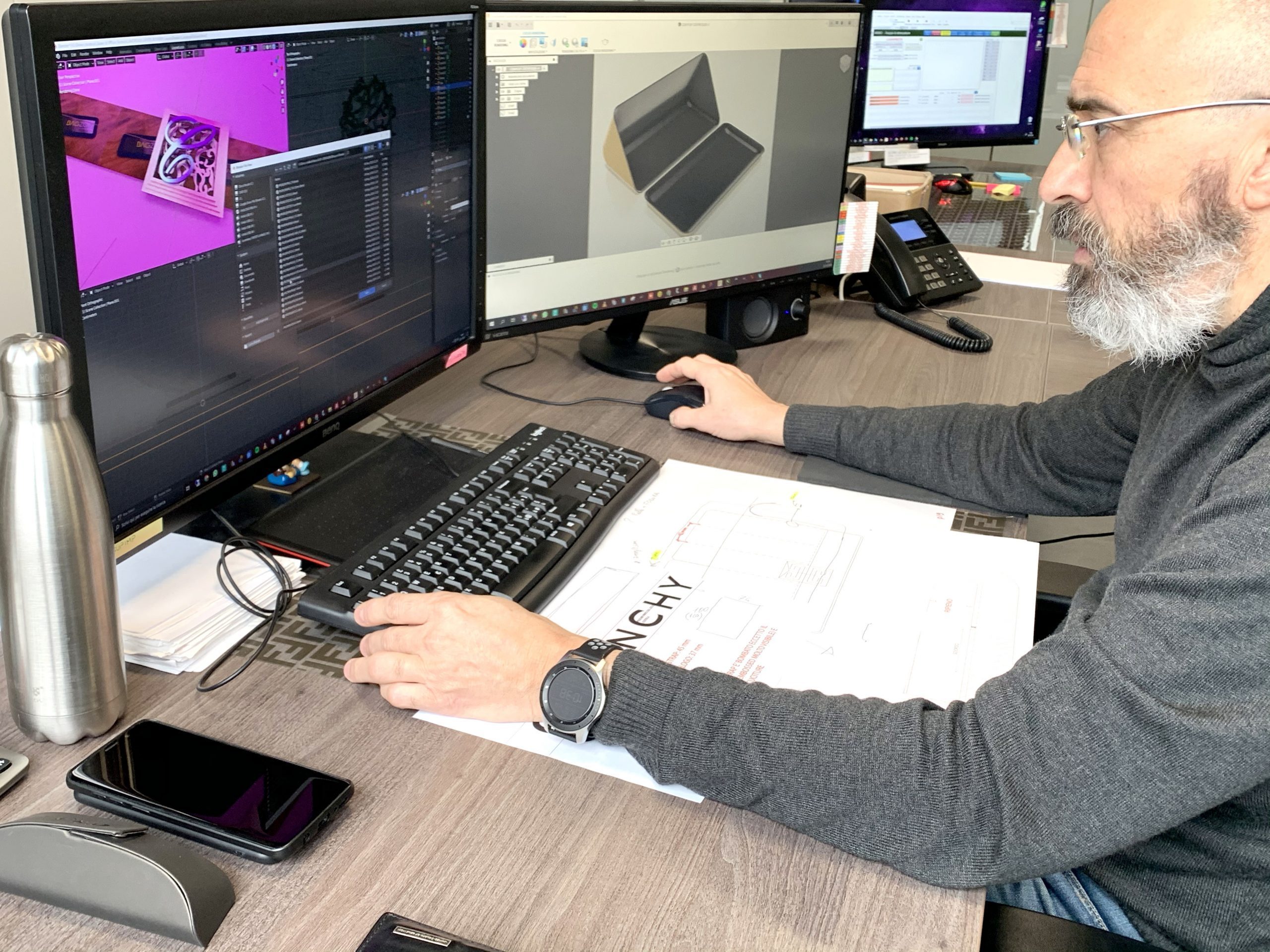

PRODUCT DEV, TECHNICAL SUPPORT & INDUSTRIALIZATION TEAM

Research and development is conducted with the aim of anticipating market trends and always offering innovative, trendy and diversified solutions.

PD & Trend Research

All of the stages involved in bringing a product from concept or idea through production phase. Starting from the client request, then dentifying a need made of colors, materials and the final use, our team puts in the effort and applies their creativity to devising a product which might serve the needs.

Timing is always a critical path, that’s why we have fine-tuned a kind of research of samples and swatches taken from our enormous archive. That allows to show techniques and material idoneus to develop a proper sample in a very short time.

Technical Support

Each new product requires the development of files, equipment, molds, specific for the required technique.

In Most we have a department of specialized technical designers able to create executive files for printing, drawings of screen printing frames, CAD and laser cutting files, molds for high frequency processing and all the accessories necessary for both the prototype development phase than for the productions.

Industrialization Team

After prototype and sampling comes the industrialization phase, probably the most delicate because it will determine the success of the product, compliance with production planning and the maintenance of pre-established quality standards.

In Most the industrialization team works closely with the development team. This guarantees essential continuity to the project, executive control in the various phases and targeted interventions to optimize all processes.

The merger of 4 companies gives rise to a reality capable of offering a wider choice of products and processes, the possibility of mixing them to obtain unique personalizations, quality controls during all the step of production (all internal) and a greater productivity.

Located in Pistoia, a small town in the heart of Tuscany, in a strategic position, a few minutes from the leather district of the Florentine area. It was founded in 2001 as a converter company and immediately focused on the personalization of clothing, leather goods, footwear and fashion accessories.

The inclusion of internal production leads to rapid expansion, which continues, thanks to continuous research, investments in machinery, plants and technologies in the name of innovation, expanding types of processing and production capacity.

Production within the plant allows techniques to be superimposed, to monitor product development and production, optimizing timing and the strong commitment of R&D and technical offices enrich the background of almost twenty years of experience with a careful look at materials, trends and new technologies

It is a recently established company but with a long experience in the screen printing sector, able to design and produce direct and transfer screen printing on leather and many other materials, which can also be combined with other processes such as high frequency, pad printing.

The inks used can be combined with other processes such as spraying in airbrushing, laser printing and padding in order to further ennoble the product.

It is possible to print on leather, eco-leather, PVC, PU and on foils also with metallic, glitter, iridescent, reflective effects or embossed and glossy / matt effects.

Thanks to our technologies, we can apply, through the lamination process, special polyurethane protections to give the product maximum resistance to light and rubbing.

More and more companies carry out high-frequency processing, Creative.com was undoubtedly if not the first, one of the first to apply this technique in the world of fashion for clothing, leather goods, footwear and accessories.

For this reason, it realizes in its offer the inestimable value of the experience gained over decades of partnerships with the major world brands.

Refined technical solutions are the result of a deep knowledge of this technique, declined in: high frequency reliefs, HF + color reliefs, HF Weld&Cut and Weld&Tear. To this package are added HD-thermoforming, inlay and lamination techniques.

TXC was founded in 2011 as a unique and new reality in the sale of fabrics and products for car furniture and faces the world as a young and creative company, based on technical products, able to give an original and innovative touch.

The products that TXC offers are knit and velvet fabrics, plain or jacquard, synthetic microfibres and furs with an infinite range of colors (also on request) and various types of finishing for an ad-hoc final accent.

From the joint venture with Most, a collection of products developed specifically for the world of fashion are born, absolutely innovative technological fabrics, capable of creating exclusive looks for clothing, footwear and bags.

Contact

P.IVA 01857760977

Ufficio del Registro: Pistoia

Codice REA: 164737

Capitale sociale: 50.000 €